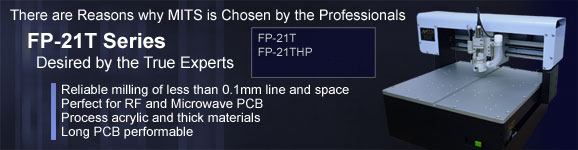

Within various manufactures producing and distributing desktop

type prototyping machine,

why does MITS prototyping machines are selected and used by

well-experienced experts

of prototyping?

Below are explanations of the key elements which our customers

observe and inspect

before purchase and how it leads to satisfactory use.

Mill 0.1mm (100µm) line and space.

|

|

Lately, the prototyping machine has been

applied to fabricate RF circuit boards and high-precise

accuracy of lines and spaces are strongly required.

For instance, to fabricate lines and spaces of 100µm,

it is unobtainable with neither other competitor's prototyping

machine nor conventional etching method (using chemical

solutions). MITS prototyping machines are the only machines

capable of performing this quality and precision, receiving

recognition from the customers working with RF around

the world.

Read more>>

|

Does high spindle revolution equal top-of-the-line

machine?

|

|

In mass production factory for print circuit

boards, spindle motor with 200000 revolutions is installed

for enhancement of productivity and drill holes for

about 700 hit per minute. With the high revolution spindle

motor, the motor size is over 65mm in diameters, costing

high price, and the maintenance is very important.

We consider that for desktop type prototyping machine,

it is much valued to select suitable revolutions for

fabricating prototype boards more easily

Read more>>

|

Processing Materials Other than PCB

|

|

The main application for prototyping machine

is to fabricate PCBs. There, however, are occasion where

the user may desire to process materials other than

PCB.

For such a case, we have selected suitable models.

Read more>>

|

Fabrication for boards larger than the working area

is accomplished.

|

|

Fabrication for boards larger than the

working area is accomplished with combination of EASY

CAD and the camera.

Read more>>

|

|

MITS

General Catalog

English

(PDF file / 1.8MB)

MITS Electronics

E-MAIL

Contact us : Inquiry Form

|