Vacuum table

These days, the needs of customer for processing the thin substrate

by using the PCB prototyping machine increases.

It is suitable to use vacuum table when processing on the thin

substrate materials.

Two models of the vacuum tables

MITS handles two kinds of vacuum tables. Please choose one in

accordance with

your purpose.

Popular model VT-ABS

Popular vacuum table made of the porous plastic resin. Compliant

with the substrate board thicker than 200µm

|

|

| Items |

VT-ABS |

| Working area W x D (mm) |

300 x 170 / 229 x 295 |

| The thinnest substrate thickness (µm) |

200 |

| Material of the porous surface |

Plastic resin |

| Vulnerability |

Strong |

| Price |

Affordable |

| Compliant model |

FP-21T, FPZ-31AT

/ Eleven Lab, Auto Lab |

|

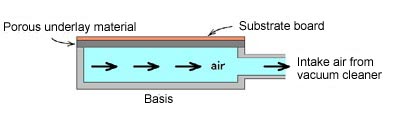

The principle of

the vacuum table and its advantage

The fundamental principle is shown above.

The advantage is to aspirate the substrate very firmly, instead

of fixing them by

Scotch tape.

Material and the surface flatness

The crucial factor in choosing the vacuum table is the thickness

of the substrate board.

In case of processing the thin substrate board, you need to choose

the vacuum

table whose surface flatness is sufficient. If the surface flatness

is bad, it causes

uneven width of the track or penetration of the tools into the

substrate board.

In case that the end mill penetrates

the substrate, the vacuum table

will not be able to function

When the surface of the porous table gets damaged, the aspiration

performance and the flatness become deteriorate. Therefore, in

processing the substrate, we recommend that you should avoid drilling

and routing and that you should perform the milling not to penetrate

the substrate.

|

Fine Processing

MITS PCB prototyping machines are suitable not only for typical

PCB prototyping but also for fine processing of various types

of materials.

MITS

General Catalog

English

(PDF file / 1.8MB)

MITS Electronics

E-MAIL

Contact us : Inquiry Form

|