|

||||||||||

|

|

||||||||||||

When making boards with fine patterns,

we usually adopt the incremental

milling method |

||||||||||||

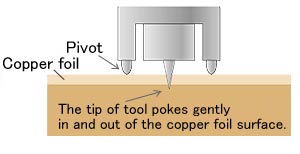

| Contact Board Making System | |

| This system leaves

the thin trace of pivot touch on the surface of

copper foil. (But this pivot does not leave any scratch.)

|

|

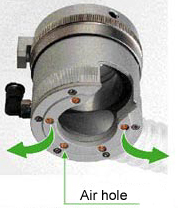

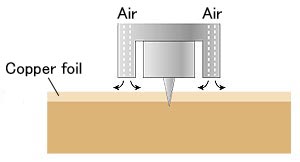

| Non-Contact Board Making System | |

As the jet of air pushes

down the board without touching, this system leaves

no trace on the copper foil. Therefore, this system

is suitable for the processing of thin or soft

board materials. However, additionally you have

to have an air compressor.

|

|

50µm(2mil) line and space, the state of the art!

FP-21T Precision

Stepping method and non-contacting pressure foot lead to the fine processing technology

Fine Processing

MITS PCB prototyping machines are suitable not only for typical PCB prototyping but also for fine processing of various types of materials.

MITS General Catalog

English

(PDF file / 1.8MB)

MITS Electronics

Contact us : Inquiry Form

MITS USA, Inc.

E-mail :