When milling the track as thin as 0.1mm, 0.05mm(50µm) When processing the 0.1mm, 0.05mm (50µm), we recommend using the stub end type end mills impervious to the slight change of the end mill's depth.

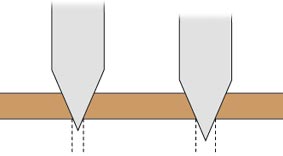

However, the stub end type end mills are so thin and fragile that we need to employ the stepping method for processing. Stepping Milling Method As the milling line gets thinner, processing condition becomes ever more crucial. When the diameter of milling bit becomes lower than 100µm, the milling bits become very fragile, leading to increase burrs. Therefore, in processing the milling bit thinner than 100µm, we employ the "stepping method" that process the PCB gradually, which is suitable for the small radial milling bit. In using the copper foil of 18µm thickness, we mill the board graually by several steps . (The depth of single milling is 5µm) With this method, you can process the PCB without burrs or breakage even if you use the small radial milling bit. >>Watch the movie clip (1474KB) Difficulty in processing the 0.1mm milling track by ATC machine As I stated above, for milling 0.1mm wide track, it is imperative to calibrate the depth of end mills very delicately. Especially, by the processing using the end mills whose tip is angular, the depth of the several micron order difference influences the track width. This delicate calibration procedure has to be done manually. Therefore, it is very difficult to calibrate the protrusion of the end mills automatically in order to mill the 0.1mm wide track. 50µm(2mil) line

and space, the state of the art! |

FP-21T Precision Stepping method and non-contacting pressure foot lead to the fine processing technology MITS General Catalog  English (PDF file / 1.8MB) MITS Electronics Contact us : Inquiry Form |

||||||||||||||||||||