Samples > Aluminum

core PCB and practical use of prototyping machine > PCB

Quality Inspection

PCB Quality Inspection using a Prototyping Machine

and application for IC's

PCB Quality Inspection

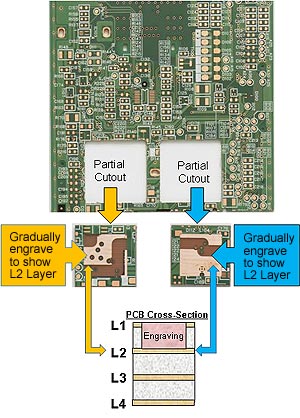

You can inspect quality of inner layer of a multi-layered circuit

board

with MITS's PCB prototyping machines.

- Check cross-section of a circuit board by counter routing.

- Inspect inner layer patterns by engraving outer

layer.

- Partial cutting of patterns.

|

|

PCB Cross-Section View |

Technical Challenges

|

|

MITS prototyping machine can resolve

the technical callenge

|

| - |

Extremely accurate cutting depth control is

required to gradually engrave outer layer without destroying

the inner layer.

|

|

MITS PCB prototyping machines ensure highly

challenging tasks by precisely controlled X, Y, and Z

axes, ruggedized mechanism, highest level of flatness

and orthogonality.

|

| - |

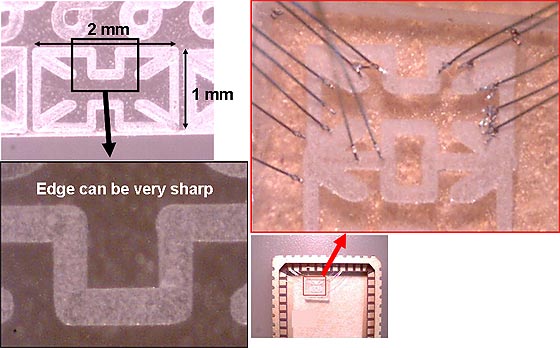

Highly precise milling is required to cut a

pattern without damaging surrounding patterns. |

Our unique "step

milling" function makes it easy to engrave patterns

in multiple paths. In each milling step, the cutting depth

is increased with a small increment assuring smooth and

accurate cutting of hard to mill material such as Aluminum

based PCB. |

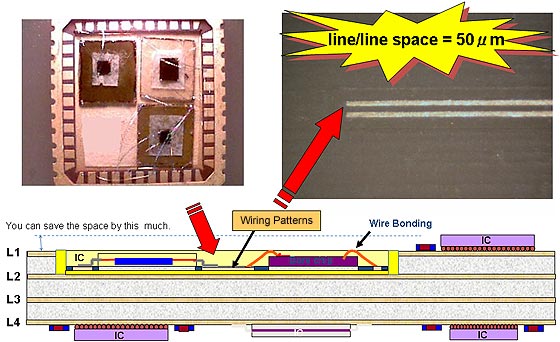

Embedded PCB Technology (IC's embedded method)

Once you get used to machine operation, this type of work is

no longer a fantasy!

Embed IC's in engraved area. (Recommended model:

FP-21T Precision)

Sample of IC fabrication

A thin film is processed with an FP-21T

Precision, then bounded in an IC package to make an IC.

Note: A bounding machine was used for bouding. |

50µm(2mil) line and space,

the state of the art!

FP-21T Precision

Stepping method and non-contacting pressure foot lead to

the fine processing technology

MITS

General Catalog

English

(PDF file / 1.8MB)

MITS Electronics

E-MAIL

Contact us : Inquiry Form

|