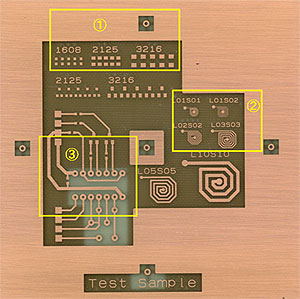

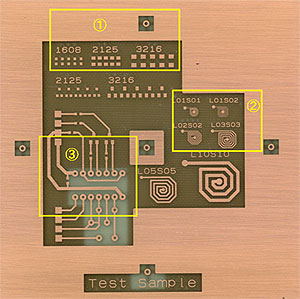

The Point where you should check for the processing quality

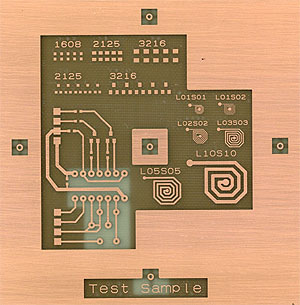

This board shows a pattern for checking the processing quality

made by our customer who was considering purchasing our PCB

machine.

|

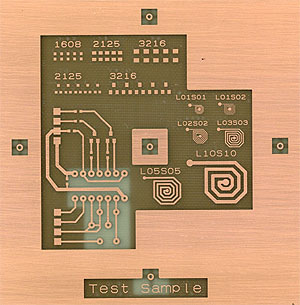

Board material : FR-4

Board size : 100mm x 100mm

Board thickness : 1.6mm

Copper layer thickness : 35µm double sides

Processing Condition

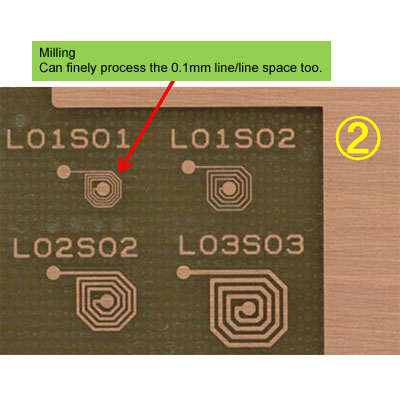

Incremental Milling

Spindle Speed

Milling : 30,000min-1

Drill & Routing : 40,000min-1

Head Travel Speed

Milling at 0.1mm point : 5mm/sec

Other milling : 12mm/sec

Processing the outline : 2mm/sec |

|

Machining time : Total 131 minutes

TOP : Milling (Contour machining)

0.1mm : 3 min.

0.2mm : 5 min.

0.3mm + 1.0mm : 80 min.

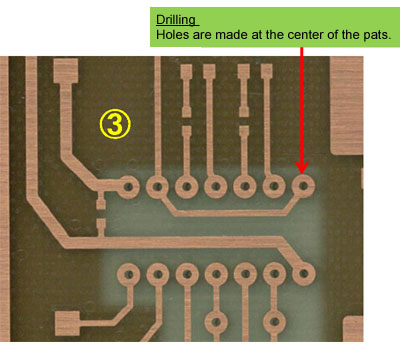

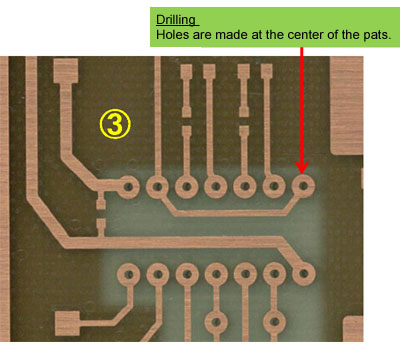

Drilling (Through-hole formation)

0.8mm : 3 min.

BOTTOM: Milling (Contour machining)

0.3mm + 1.0mm : 35 min.

Forming (Processing the outline)

1.5mm : 5 min.

|

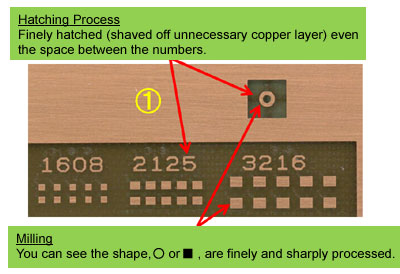

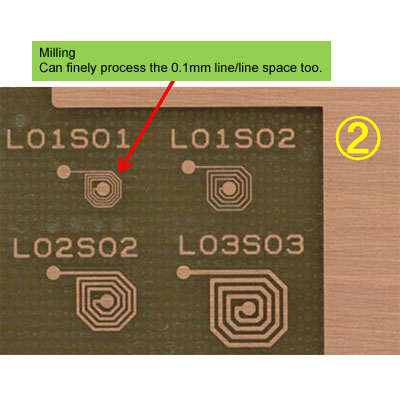

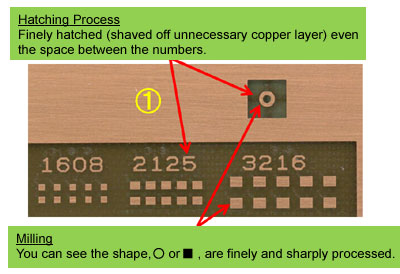

Close-up picture

|

50µm(2mil) line and space,

the state of the art!

FP-21T Precision

Stepping method and non-contacting pressure foot lead to

the fine processing technology

MITS

General Catalog

English

(PDF file / 1.8MB)

MITS Electronics

E-MAIL

Contact us : Inquiry Form

|