|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Recommended model |

|

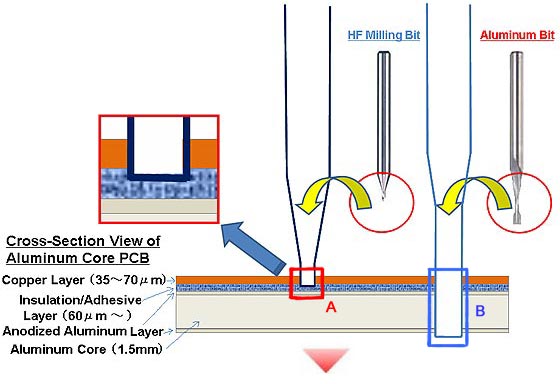

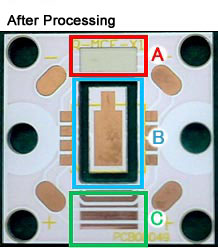

Example of processing method

| Millig | Couter Routing | ||

| Tool | HF Milling Bit | Tool | Aluminum Bit |

| Milling Method | Incremental Milling | Routing Method | 3 stage step milling |

| Spindle Speed | 30,000 RPM | Spindle Speed | 40,000 RPM |

| Head Travel Speed | 6mm/sec (0.3mm HF Milling Bit) 12mm/sec (0.5mm HF Milling Bit) |

Head Travel Speed | 2mm/sec (1.0mm Aluminum Bit) |

50µm(2mil) line and space, the state of the art!

FP-21T Precision

Stepping method and non-contacting pressure foot lead to the fine processing technology

MITS General Catalog

English

(PDF file / 1.8MB)

MITS Electronics

Contact us : Inquiry Form

Before Processing

|

|

|||||||||||